Lee, T.U., Liu, Y. and Xie, Y.M., 2024. Composite Structures, p.117875. [Link]

Curved surfaces may be approximated using polygonal panels to simplify complex architectural designs, yet their constructions can be expensive due to single-use moulds producing unique panels. To reduce costs, strategies like planarizing and reducing the number of different panels have been suggested, which are increasingly achievable with advancing digital fabrication technologies. However, current subtractive and additive manufacturing techniques face challenges in producing complex 3D shapes and large volumes, respectively. Combining these two techniques has been attempted, mainly with small 3D-printed nodes, leaving the direct realization of curved surface approximations unexplored.

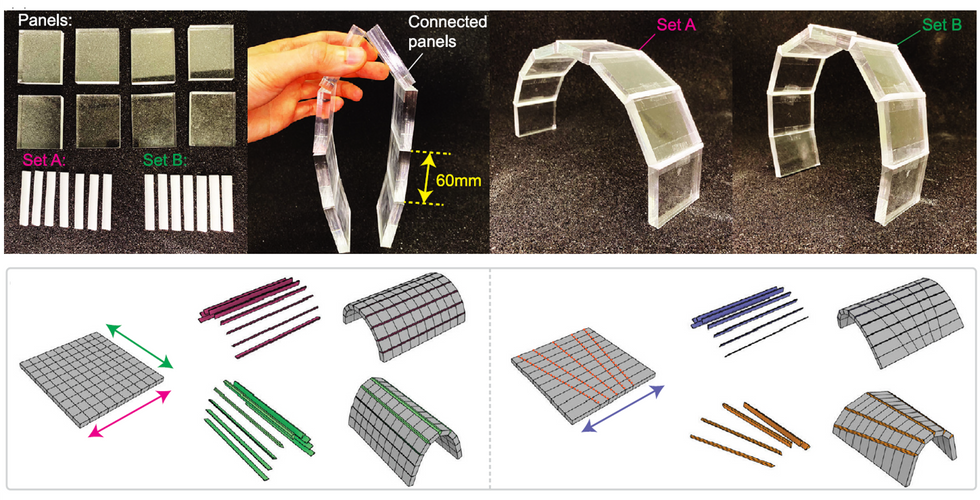

This paper extends the thick-panel origami theory to introduce planar-thick panels and 3D-printed gap fillers for cost-effective constructions. It presents a computational workflow to transform meshes into non-intersecting panels while preserving edge connectivity and frame-like gap fillers with minimized volumes. Physical prototypes demonstrate significant cost savings compared to direct 3D printing. All prototypes are accurate within a 10 mm material thickness due to the guidance of the gap fillers. The finite element analysis shows that structural performance is greatly influenced by the material properties, especially of panels, due to their relatively larger volume. Numerical examples are also presented using the 𝑘-means clustering-optimization method to reduce the number of different panels.